Lucie rowe

This small-scale project is a great way to get started in metalworking and a fun accent to any wardrobe.

(2) silver forks

Rotary tool with metal cutting disc, sanding disc and wire brush.

safety glasses and gloves

screw

propane torch

heat resistant work surface

tongue and groove or slip lock pliers

needle nose pliers

Jump rings, swivels, and lobster clasps.

Security Alert: Do not substitute gold plated flatware for silver plated flatware. Gold plating can disintegrate and even explode when heated.

1. Determine where to cut the fork handle. Most hairpins have a natural break in the handle, either a place where it tapers or even a decorative ring or design. If the fork has one of these, cut there. If not, cut the handle about an inch below where it opens for the teeth.

2. Carefully secure the end of the fork in a vise. Wearing gloves and safety glasses, cut off the fork handle with a rotary tool fitted with a metal cutting wheel; a hacksaw will also work. Security alert: Always wear safety glasses and gloves when cutting metal. Also, don't touch freshly cut metal, it's hot.

3. Use a pair of pliers to remove the fork from the vise and set it aside. Repeat the process to cut the other bobby pin.

4. When both forks have been cut to length, lay them, points down, on a heat-resistant surface. This surface can be a piece of cement board, cement, or metal.

5. Use a propane torch to heat the forks – heating the metal makes it much easier to bend. Keep the flame moving and hold it about 2" from the silver, heating until the forks are cherry red. Safety Alert: Wear eye protection and gloves when heating forks, and do not handle hot forks or hot end of torch. Follow all fire safety precautions and keep children and pets away when heating metal.

6. Let the forks cool down naturally at room temperature. Don't rush the process by putting them in an ice bath or cold water. Don't worry if the metal is slightly discolored; which will be fixed in a later step.

7. When the metal has cooled, place the fork in a vise, points down, with the front of the fork facing you.

8. Cover the teeth of the slip-resistant or tongue-and-groove pliers with tape to protect the silver. With covered teeth, grab the remaining part of the fork handle with the pliers and gently bend it towards you to create the shape of the bracelet. Make the bends gradually, easing the metal into the desired shape. Periodically remove the fork from the vise to check for tightness.

9. Bend the second bobby pin the same way.

10. Once both forks are bent, place one fork back in the vise with the bend facing out. Leave only about 1" of the teeth secured in the vise.

11. Use the tape-wrapped pliers to grasp the fork at the base of the tines and gently bend the piece toward you, approximately 90 degrees. Repeat for the other fork..

12. Use needle-nose pliers to bend the teeth further and create a curl or loop at the tip of each tooth.

13. Use a rotary tool with a small wire wheel attachment to remove any discoloration caused by heat.

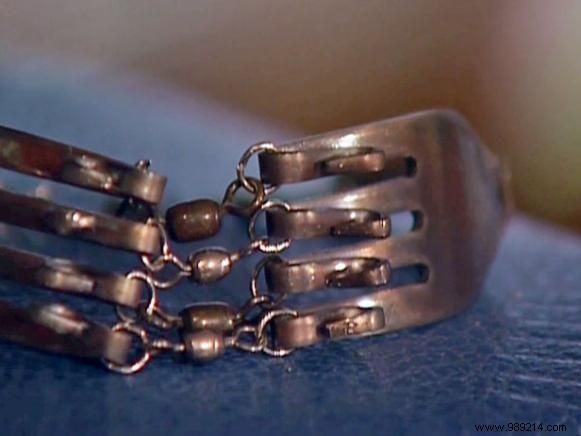

14. Place the jump rings over the threaded fork teeth and use additional jump rings or swivels to connect the forks together. When the bracelet is finished, weld the jump rings together so the weight of the bracelet doesn't pull them apart.

15. Instead of using jump rings, you can also "weave" your teeth together. Slide the forks together until the threaded teeth line up. Then insert a single cut from another bobby pin (or left over from another project). Once you are sure of the fit, remove the single prong, heat it with the propane torch, and allow it to cool naturally. Then slide it back onto the curly teeth. Twist each end of the single prong to hold it in place and prevent it from snagging on clothing.

16. To connect and finish the bottom of the bracelet, drill a hole in the handle end of each of the bobby pins. Add a jump ring and silver swivel to each hole, then fasten with a lobster clasp. To make it even simpler, make the large curves of the fork fit your wrist a little more and wear it as a bracelet.